Meeting the Building Regulations

Benefiting from the excellent environmental aspects of EPS Springvale products are quick to install and are suitable for improving the thermal performance by making substantial contributions to reducing CO2 emissions and improved energy efficiency of buildings.

Heat loss from the floor, wall and roof of any construction can significantly affect the overall performance of the fabric of the building.

Building Regulations Approved Document L take a whole-building approach to fabric energy efficiency incorporating U-values & Psi values, Springvale products are well placed to offer excellent thermal performance achieving significantly low U-values & Psi values for improved SAP ratings.

U-Values

U-values are bespoke calculations for each individual element of the building. Springvale products are versatile and can adapt to the individual floor, wall or roof design. For example the Beamshield U values are calculated using numerical analysis; based on a detailed computer generated model calculation, that allows for multi-dimensional (non- uniform) heat flow.

Our Beamshield systems can achieve U-values as low as 0.06W/m2K by offering a continuous layer of insulation above and/or below the suspended concrete beams.

The following examples use a more simplified method known as the combined method which combines the upper and lower limits of the thermal resistance of the element.

Ecobead can easily achieve U-values as low as 0.17 W/m2K when installed into a 150mm cavity width.

U values of 0.09W/m2K can easily be achieved when using 300mm thick Platinum Floorshield above a concrete slab.

Using 150mm thick Platinum Warmsqueeze between the rafters and 75mm thick Platinum Warmsark above the rafters will achieve 0.15W/m2K U value.

U-Values

U-values are bespoke calculations for each individual element of the building. Springvale products are versatile and can adapt to the individual floor, wall or roof design. For example the Beamshield U values are calculated using numerical analysis; based on a detailed computer generated model calculation, that allows for multi-dimensional (non- uniform) heat flow.

Our Beamshield systems can achieve U-values as low as 0.06W/m2K by offering a continuous layer of insulation above and/or below the suspended concrete beams.

The following examples use a more simplified method known as the combined method which combines the upper and lower limits of the thermal resistance of the element.

Ecobead can easily achieve U-values as low as 0.17 W/m2K when installed into a 150mm cavity width.

U values of 0.09W/m2K can easily be achieved when using 300mm thick Platinum Floorshield above a concrete slab.

Using 150mm thick Platinum Warmsqueeze between the rafters and 75mm thick Platinum Warmsark above the rafters will achieve 0.15W/m2K U value.

Psi Values

Psi values are based on the heat loss through (non-repeating) thermal bridges i.e. the junctions between the plain building elements or around openings.

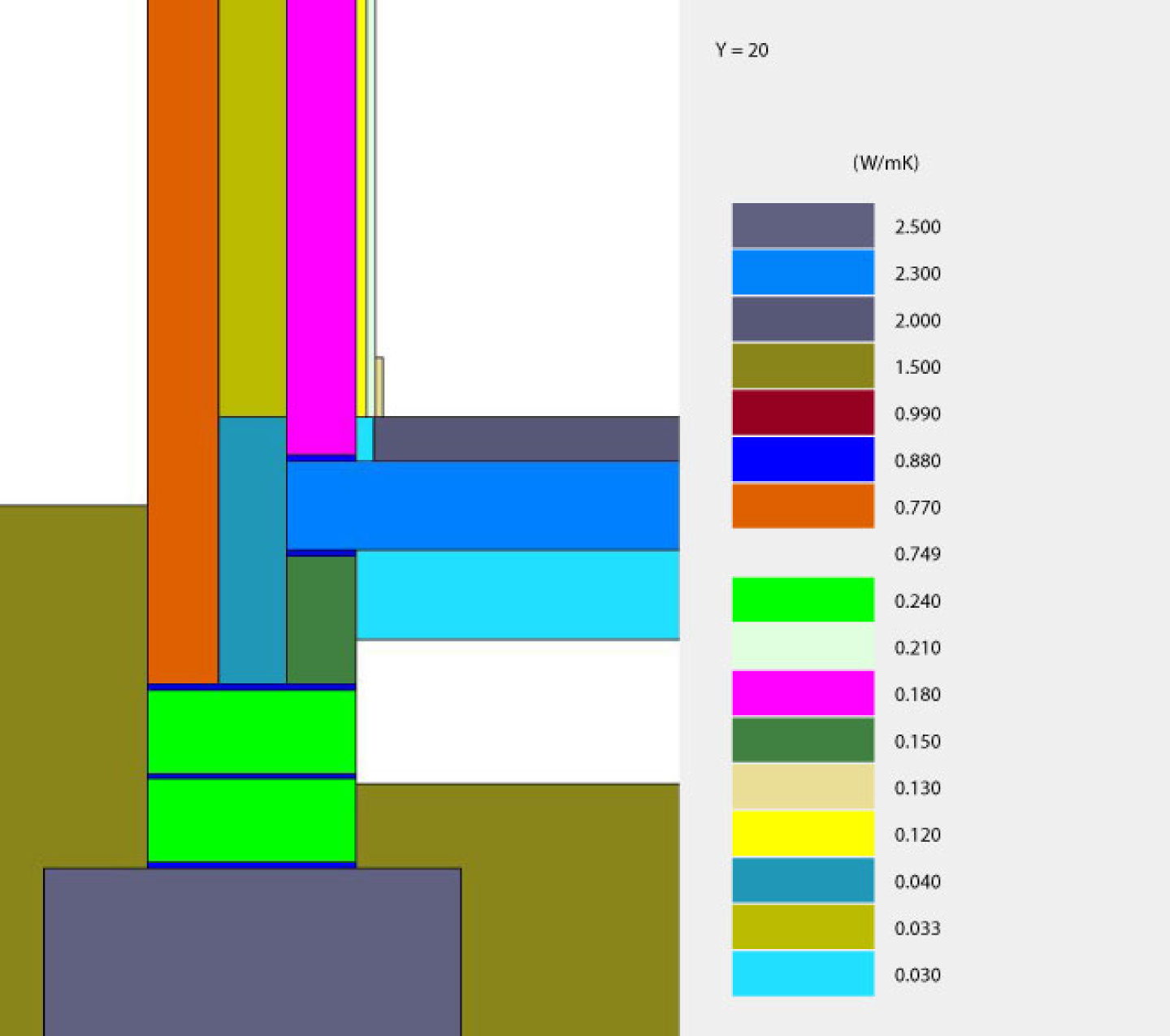

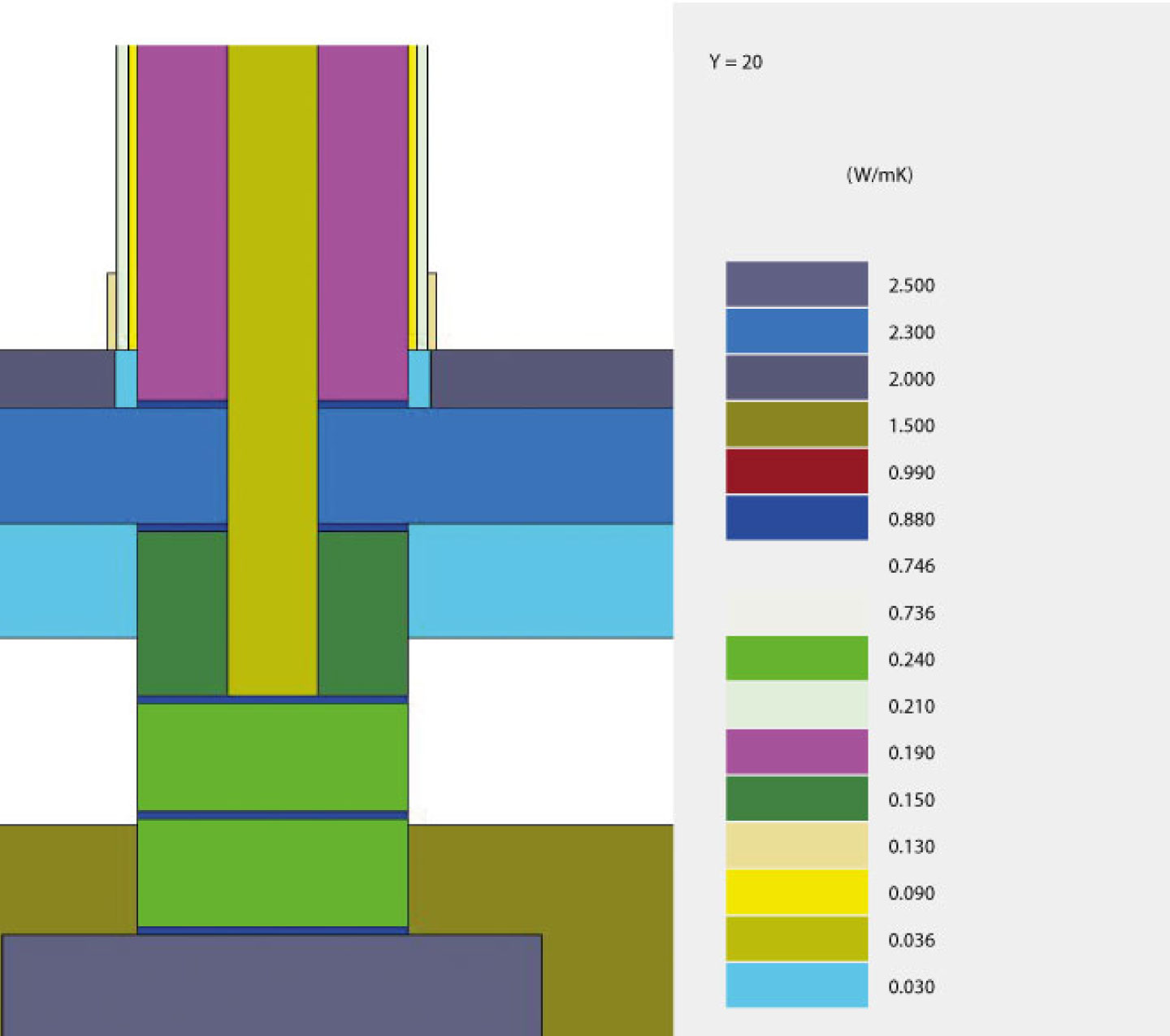

Psi values are derived from two dimensional or three dimensional models using state of the art software. The model is constructed from the dimensions and thermal values (W/mK) from all the components used in the element design.

By the adoption of good practice at the design stage there are considerable savings to be made in the amount of heat lost through bridges at critical junctions in buildings. Up to 30% of heat in the fabric of a typical building can be lost as a result of thermal bridging.

Springvale promote good practice in the use of all of its EPS insulation products and can provide Psi values for critical junctions

Linear Thermal Bridging

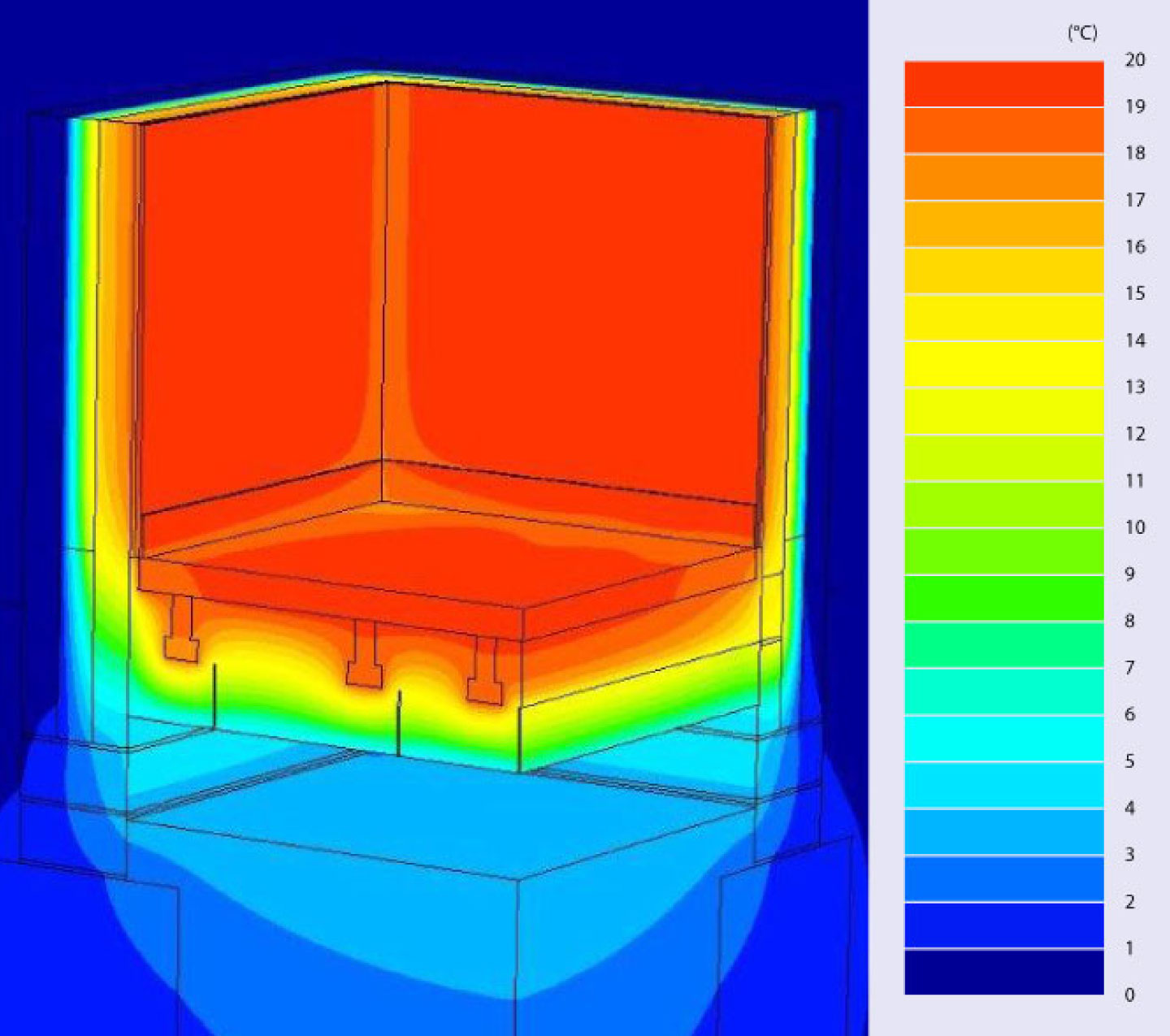

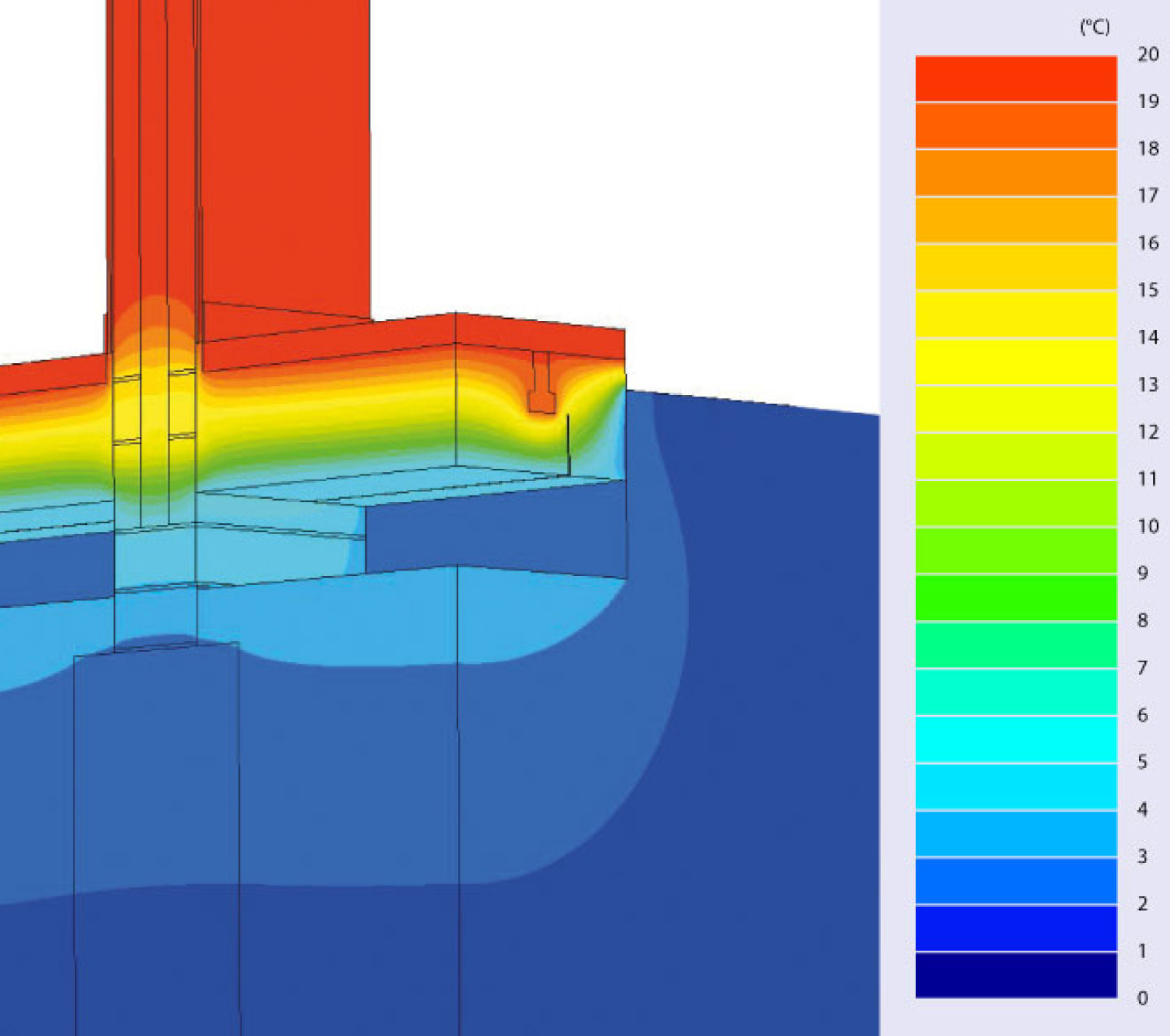

It is vital that the data used in all calculations is accurate and up-to-date. The 3D thermal graphic shows clearly the benefit of a well-designed junction using Springvale products. The corner junction is particularly sensitive to temperature fluctuations across the junction and should be no less than 0.75 of the internal temperature used in the calculation.

A well designed junction should include components that, as well as being structurally sound, have a good thermal performance. The location and coverage of these thermal components is equally as important.

The thermal value 2D graphic shows some typical components that may be used to achieve a good Psi value.