Sustainability & EPS Products

Expanded polystyrene (EPS) is an excellent choice for use as insulation and other applications, consisting of 98% air means only 2% of any product is polystyrene material.

With its outstanding thermal insulation qualities EPS is a first choice material for numerous construction applications. Using EPS can reduce CO2 emissions by up to 50%, offsetting its small carbon footprint and giving maximum return for minimal resource and can also make a significant contribution to reducing fossil fuel use for heating and cooling of buildings which in turn, helps reduce SO2 and SO3 emissions, a major cause of acid rain.

Using less than 0.1% of global oil consumption to manufacture EPS, it can save up to 200 times its own resource in thermal energy saving, bringing considerable energy and resource-saving benefits.

A durable, inert, non-toxic, rot proof and 100% recyclable product, the performance of EPS is expected to last at least the life time of the building in which it is used.

The amount of carbon monoxide and particulates given off by EPS during combustion is a small fraction of that emitted by wood or cardboard.

The manufacture of EPS is safe for the environment as only steam is used during the manufacture process. There is no waste in the process as all off-cuts are re-cycled back into the production process.

Facts About EPS

EPS is 98% air. This makes EPS a uniquely resource-efficient material with a small carbon footprint

EPS is extremely lightweight; this helps to reduce fuel consumption, when products are transported compared to other heavier materials

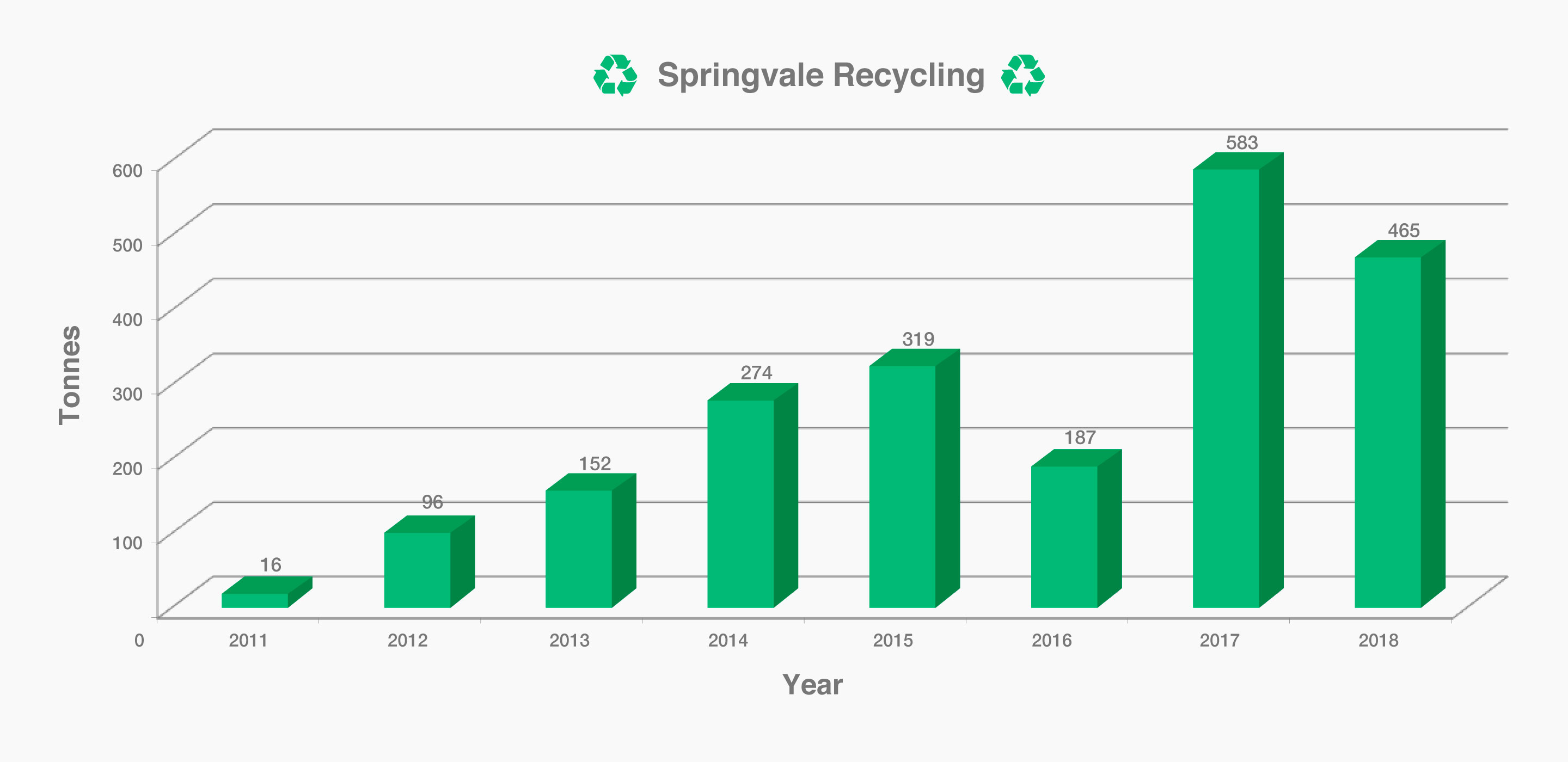

Thousands of tonnes of EPS are recycled every year in the UK. As a single polymer EPS is straightforward to recycle

EPS uses Pentane as its blowing agent and is HFC, CFC and HCFC free. Pentane has a low Global Warming Potential (GWP) of less than five (the EU does not register pentane as a substance hazardous to human health or the environment).

Facts About EPS

EPS is 98% air. This makes EPS a uniquely resource-efficient material with a small carbon footprint

EPS is extremely lightweight; this helps to reduce fuel consumption, when products are transported compared to other heavier materials

Thousands of tonnes of EPS are recycled every year in the UK. As a single polymer EPS is straightforward to recycle

EPS uses Pentane as its blowing agent and is HFC, CFC and HCFC free. Pentane has a low Global Warming Potential (GWP) of less than five (the EU does not register pentane as a substance hazardous to human health or the environment).

The inert and non-toxic nature of EPS provides stability in landfill because it does not biodegrade and leach chemicals into the water system or gases into air that could contribute to global warming.

Life-cycle analyses demonstrate that EPS has exceptional qualities as a construction material.

It has a Zero Ozone Depletion Potential (ODP) and a low Global Warming Potential (GWP) and achieves the highest possible A-Plus summary rating in the BRE Global Green Guide to Specification.

Springvale are members of the British Plastics Federation (BPF) and participates in the recycling post-construction EPS scheme.

The BPF EPS group is part of the British Plastics Federation